Basic Info

Product Description

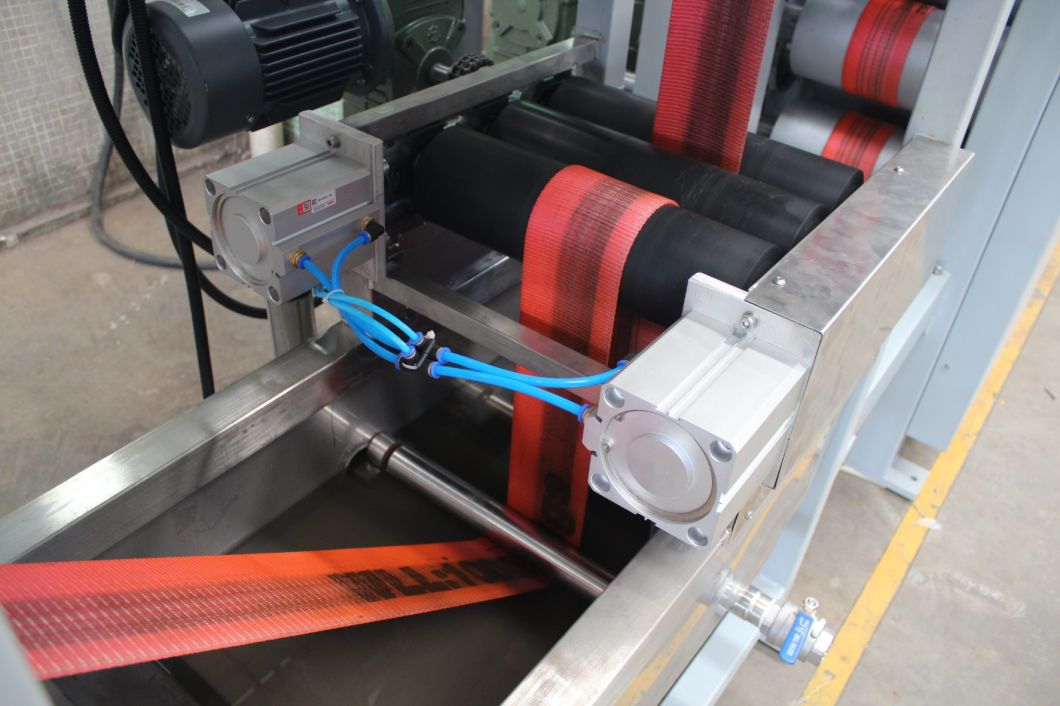

Item No:KW-820-DZ400

Size: 16800*1000*4000mm

This is high speed Sling webbings/tie down straps/lash straps continuous dyeing&finishing machine

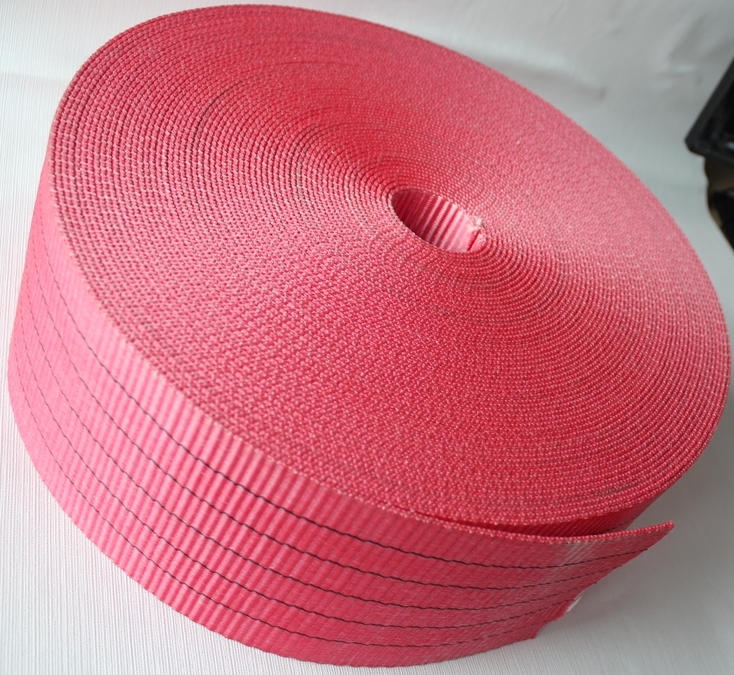

Application: The dyeing machine is especially used for dyeing textile lift slings,tie down straps,lash straps and Heavy duty belts with elongation.

Product capacity: 1-4 Pcs/time, 0-15meter/min/Pcs

Can dye both 350mm width sling webbings,heavy duty webbings,tie down straps,lash straps,etc.

With strong elongation function.

For 300mm width webbings:1 meter go into dyeing machine,1.02meter come out after dyed.

For 50mm width webbings:1 meter go into dyeing machine,1.06meter come out after dyed.

Heat System electrical/LPG or natural gas

Working Width(mm) 600

Thermofixation Chamber Tape Content(m) 60

Maximun Speed(m) 20

Maximun Number(m) 8

Control system Computer control

Processes: Feed in-dyeing groove-Infrared pre drying-hold mangle-

thermofixation-cooling system-pull mangle-take off

Company Information

KIN WAH Mechanical Industrial Co., Ltd. established in the year of 2005, has been dedicated in researching and developing KIN WAH dyeing and finishing equipment series for narrow fabric for more than twenty years. KIN WAH dyeing and finishing equipment series include High temperature Continuous Dyeing & finishing Machines, Normal temperature Continuous Dyeing &finishing Machines, High & Normal Temperature Continuous Dyeing & finishing Machines (same machine), Finishing & Starching Machine, Calender Machine for labels, packaging machines, rolling machines and relative narrow fabric Complete Plant programming. They are widely used for all kinds of narrow fabric made from polyester, nylon and cotton material, such as automobile seat belts (one end & two-ends), heavy duty tapes, textile lift slings, safety belts, luggage & bag belts, satin ribbons, ornament ribbons, labels, elastic tapes, organza tapes, curtain tapes, and cotton tapes.

Our Services

Customers:

lifting slings/webbing slings/lash strap/tie down strap: JULI Group, Murtra, Protekt, Astro, Hedef Halat, Ekas, Tsiros and Ferreterro, Dahua, Lijia, LiQiang,

Automobile Seatbelt Webbing:AUTOLIV GROUP,Oppermann, FEIMA, GuangDa

Label Ribbon:Kings, ITL, LEADERS, XINLI, WUXING,YOU FU, SHUANGLIN

Packaging & Shipping

Covered by plastic membrane within full container or less container (woodencase)