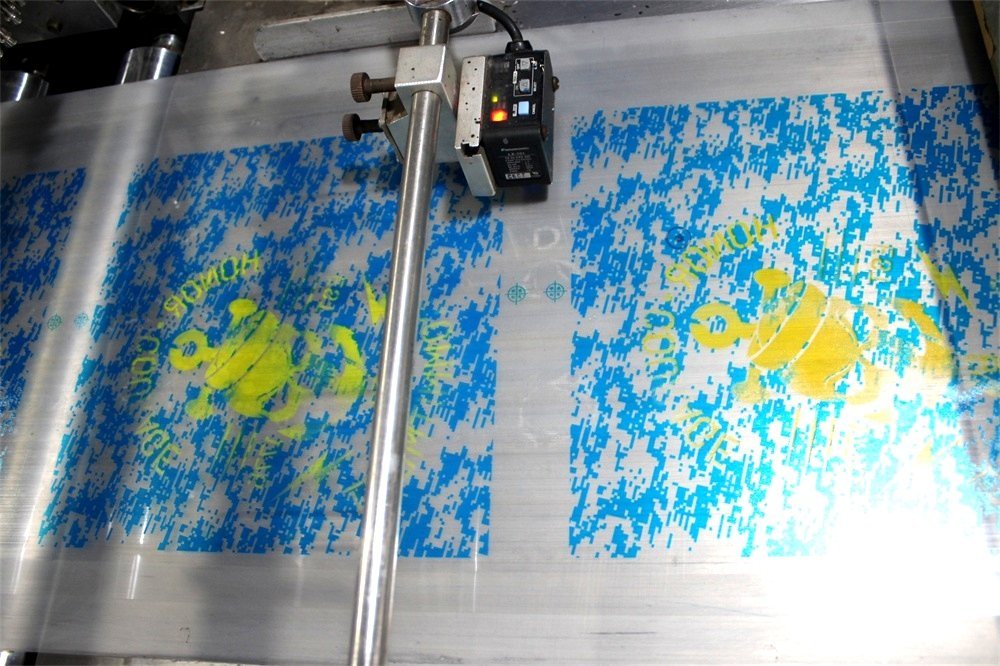

Factory selling High End Automatic Screen Printer - Bag Belts Continuous Dyeing&Finishing Machine with High Standard – Kin Wah Detail:

Basic Info

Product Description

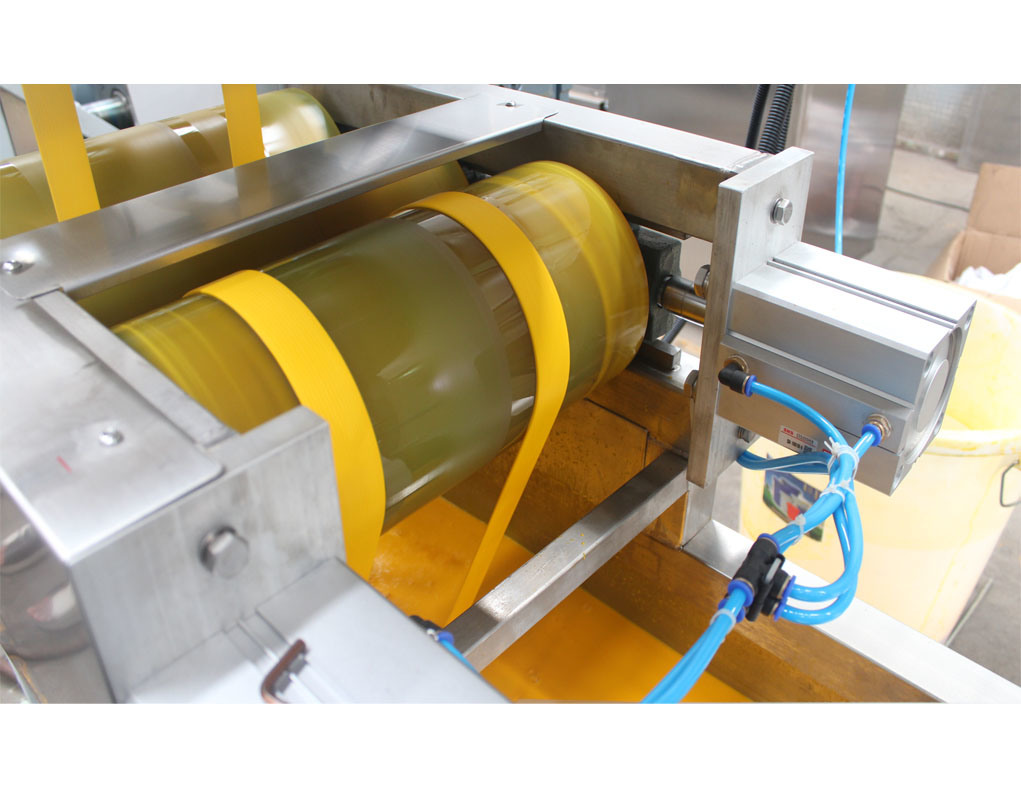

Item No:KW-800-XB400-H

Size: 15000*1000*1800mm

This is high speed luggage&Suitcase belts/webbing continuous dyeing machines for nylon webbings,and polyester webbings,safty webbings,lanyard ribbons,harness webbings and heavy duty webbings etc.

Features:

1) High efficiency

2) Power Energy Saving

3) Our patents.

4)Application: The dyeing machine is especially used for

luggage&Suitcase belts/webbing continuous dyeing machines

for nylon webbings,and polyester webbings,safty webbings,lanyard ribbons,harness webbings and heavy duty webbings with thickness below 1.5mm.

5)Product capacity: 1-12 Pcs/time, 0-35meter/min/Pcs.

Heat System electrical/LPG or natural gas/steam

Working Width(mm) 200/400/600

Thermofixation Chamber Tape Content(m) 45/60/60/80

Maximun Speed(m) 15/30/40

Maximun Number(m) 6/10/20

Control system Manual/Computer control(PLC&Touch screen)

Processes: Feed in-dyeing groove-Infrared pre drying-thermofixation chambers-chemical groove-steam chamber-washing tanks-chemical groove-hot air chamber drying&finishing unit-cooling system-take off

Customers: SATIN RIBBONS, ELASTIC TAPES continuous dyieng and finishing machines: MONTRIMS,ITL,GLOBAL LABEL, KINGS, LEADER,XINLIN,SANDING GROUP, BRAITEX, TELALA, WARRANTY, APEX, N R GROUP, SHORE TO SHORE, KNITTING CONCERN, STRETCHLINE, DUGOTEX SO ON.

KIN WAH Mechanical Industrial Co., Ltd. established in the year of 2005, has been dedicated in researching and developing KIN WAH dyeing and finishing equipment series for narrow fabric for more than twenty years. KIN WAH dyeing and finishing equipment series include High temperature Continuous Dyeing & finishing Machines, Normal temperature Continuous Dyeing &finishing Machines, High & Normal Temperature Continuous Dyeing & finishing Machines (same machine), Finishing & Starching Machine, Calender Machine for labels, packaging machines, rolling machines and relative narrow fabric Complete Plant programming. They are widely used for all kinds of narrow fabric made from polyester, nylon and cotton material, such as automobile seat belts (one end & two-ends), heavy duty tapes, textile lift slings, safety belts, luggage & bag belts, satin ribbons, ornament ribbons, labels, elastic tapes, organza tapes, curtain tapes, and cotton tapes.

Product detail pictures:

Related Product Guide:

Everything You Ever Wanted to Know About Queen | Polyester Satin Ribbons Sample Continuous Dyeing Machine

Evans’ path to gold medal a long, winding road | Sports | Luggage Belt Continuous Dyeing And Finishing Machine

"Quality to start with, Honesty as base, Sincere company and mutual profit" is our idea, as a way to build constantly and pursue the excellence for Factory selling High End Automatic Screen Printer - Bag Belts Continuous Dyeing&Finishing Machine with High Standard – Kin Wah, The product will supply to all over the world, such as: Porto , Colombia , Mongolia , We taking advantage of experience workmanship, scientific administration and advanced equipment, ensure the product quality of production, we not only win the customers' faith, but also build up our brand. Today, our team is committed to innovation, and enlightenment and fusion with constant practice and outstanding wisdom and philosophy, we cater to the market demand for high-end goods, to do experienced products and solutions.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.

-

PriceList for Elastic Laces Festooning Machine ...

-

Good Wholesale Vendors Multicolors Screen Print...

-

Factory Free sample Woven Labels Slitting Machi...

-

Professional Design Bottle Cylinderical Screen ...

-

OEM China Ultrasonic Slitting Machine - Multi-...

-

Discount wholesale Heavy Duty Webbings Cutting ...