High Quality Roll To Roll Lanyard Screen Printing Machine - High efficient heavy duty webbings continuous dyeing machine with CE Cetification – Kin Wah Detail:

Basic Info

Model NO.: KW-820-DZ400

Warranty: 1 Year

Customized: Customized

Condition: New

Machine Type: Dyeing&Finishing Machine

Power: 55kw

Main Part Material: Stainless Steel, Iron, Carbon Steel etc

Driven Type: Electirc

Phase: 3 Phases

Frequency: 50/60Hz

Max Working Temperature: 220°c

Heating System: Electrical/LPG or Natural Gas

Max Speed: 20m/Min

Drying Type: Hot Air

Trademark: KINWAH

Transport Package: Wooden Box for LCL Film for FCL

Specification: CE certification

Origin: China

HS Code: 84514000

Product Description

Wide Sling Webbing Continuous Dyeing and Finishing Machine PriceProduct Description

Item No:KW-820-DZ600

Size: 16800*1000*4000mm

This is high speed Sling webbings/tie down straps/lash straps continuous dyeing&finishing machine

Application: The dyeing machine is especially used for dyeing textile lift slings,tie down straps,lash straps and Heavy duty belts with elongation.

Product capacity: 1-4 Pcs/time, 0-15meter/min/Pcs

Can dye both 350mm width sling webbings,heavy duty webbings,tie down straps,lash straps,etc.

With strong elongation function.

For 300mm width webbings:1 meter go into dyeing machine,1.02meter come out after dyed.

For 50mm width webbings:1 meter go into dyeing machine,1.06meter come out after dyed.Heat System electrical/LPG or natural gas

Working Width(mm) 600

Thermofixation Chamber Tape Content(m) 60

Maximun Speed(m) 20

Maximun Number(m) 8

Control system Computer control

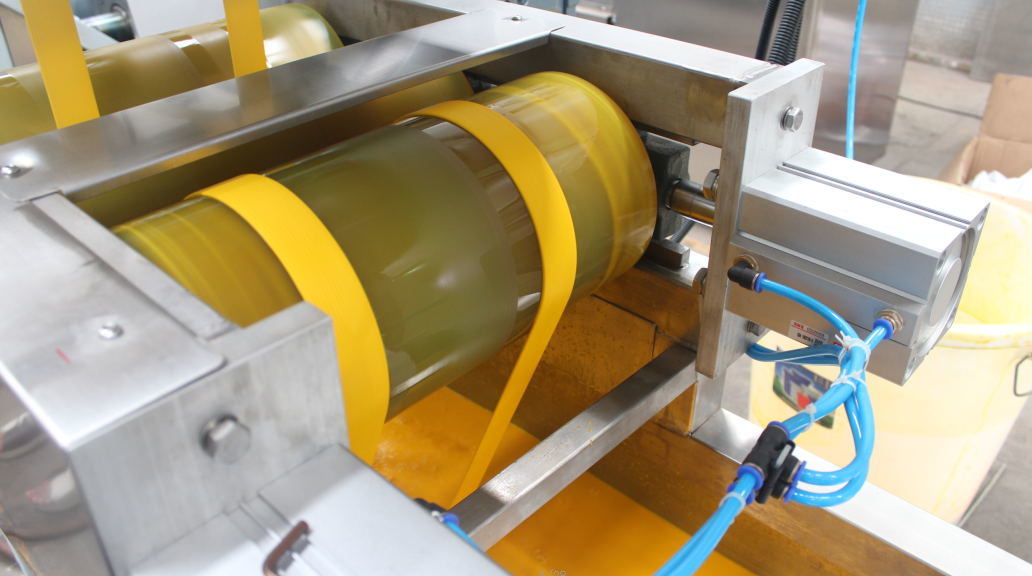

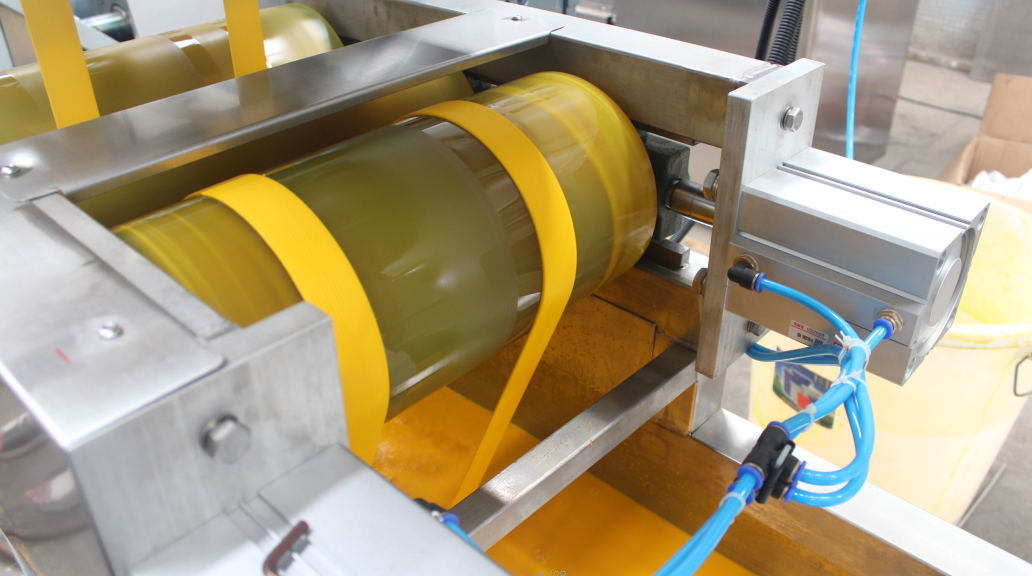

Processes: Feed in-dyeing groove-Infrared pre drying-hold mangle-

thermofixation-cooling system-pull mangle-take offCompany Information

KIN WAH Mechanical Industrial Co., Ltd. established in the year of 2005, has been dedicated in researching and developing KIN WAH dyeing and finishing equipment series for narrow fabric for more than twenty years. KIN WAH dyeing and finishing equipment series include High temperature Continuous Dyeing & finishing Machines, Normal temperature Continuous Dyeing &finishing Machines, High & Normal Temperature Continuous Dyeing & finishing Machines (same machine), Finishing & Starching Machine, Calender Machine for labels, packaging machines, rolling machines and relative narrow fabric Complete Plant programming. They are widely used for all kinds of narrow fabric made from polyester, nylon and cotton material, such as automobile seat belts (one end & two-ends), heavy duty tapes, textile lift slings, safety belts, luggage & bag belts, satin ribbons, ornament ribbons, labels, elastic tapes, organza tapes, curtain tapes, and cotton tapes.Our Services

Customers:

lifting slings/webbing slings/lash strap/tie down strap: JULI Group, Murtra, Protekt, Astro, Hedef Halat, Ekas, Tsiros and Ferreterro, Dahua, Lijia, LiQiang,

Automobile Seatbelt Webbing:AUTOLIV GROUP,Oppermann, FEIMA, GuangDa

Label Ribbon:Kings, ITL, LEADERS, XINLI, WUXING,YOU FU, SHUANGLIN

Item No:KW-820-DZ600

Size: 16800*1000*4000mm

This is high speed Sling webbings/tie down straps/lash straps continuous dyeing&finishing machine

Application: The dyeing machine is especially used for dyeing textile lift slings,tie down straps,lash straps and Heavy duty belts with elongation.

Product capacity: 1-4 Pcs/time, 0-15meter/min/Pcs

Can dye both 350mm width sling webbings,heavy duty webbings,tie down straps,lash straps,etc.

With strong elongation function.

For 300mm width webbings:1 meter go into dyeing machine,1.02meter come out after dyed.

For 50mm width webbings:1 meter go into dyeing machine,1.06meter come out after dyed.Heat System electrical/LPG or natural gas

Working Width(mm) 600

Thermofixation Chamber Tape Content(m) 60

Maximun Speed(m) 20

Maximun Number(m) 8

Control system Computer control

Processes: Feed in-dyeing groove-Infrared pre drying-hold mangle-

thermofixation-cooling system-pull mangle-take offCompany Information

KIN WAH Mechanical Industrial Co., Ltd. established in the year of 2005, has been dedicated in researching and developing KIN WAH dyeing and finishing equipment series for narrow fabric for more than twenty years. KIN WAH dyeing and finishing equipment series include High temperature Continuous Dyeing & finishing Machines, Normal temperature Continuous Dyeing &finishing Machines, High & Normal Temperature Continuous Dyeing & finishing Machines (same machine), Finishing & Starching Machine, Calender Machine for labels, packaging machines, rolling machines and relative narrow fabric Complete Plant programming. They are widely used for all kinds of narrow fabric made from polyester, nylon and cotton material, such as automobile seat belts (one end & two-ends), heavy duty tapes, textile lift slings, safety belts, luggage & bag belts, satin ribbons, ornament ribbons, labels, elastic tapes, organza tapes, curtain tapes, and cotton tapes.Our Services

Customers:

lifting slings/webbing slings/lash strap/tie down strap: JULI Group, Murtra, Protekt, Astro, Hedef Halat, Ekas, Tsiros and Ferreterro, Dahua, Lijia, LiQiang,

Automobile Seatbelt Webbing:AUTOLIV GROUP,Oppermann, FEIMA, GuangDa

Label Ribbon:Kings, ITL, LEADERS, XINLI, WUXING,YOU FU, SHUANGLIN

Packaging & Shipping

Covered by plastic membrane within full container or less container (woodencase)

Product detail pictures:

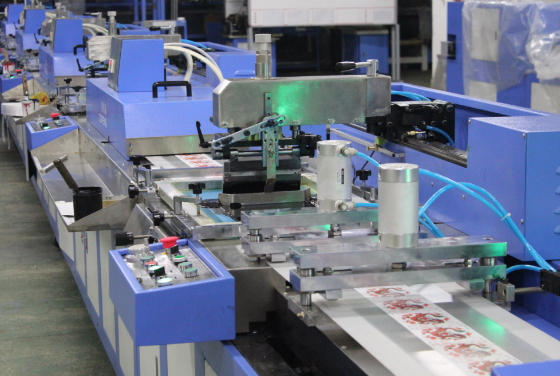

Related Product Guide:

Ricoh to acquire ColorGATE in move to strengthen industrial printing business | Labels Screen Printer

UPS’s $20 Billion Problem: Operations Stuck in the 20th Century | Labels Screen Printer

It can be a great way to enhance our solutions and service. Our mission would be to build inventive products to consumers with a superior working experience for High Quality Roll To Roll Lanyard Screen Printing Machine - High efficient heavy duty webbings continuous dyeing machine with CE Cetification – Kin Wah, The product will supply to all over the world, such as: Albania , Benin , Chicago , Adhering to the management tenet of "Managing Sincerely, Winning by Quality", we try our best to provide excellent products and service to our clients. We look forward to making progress together with domestic and international clients.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!

-

Factory making Climbing Rope Machine - SPE-300...

-

Reasonable price Sale Printing Machine - Econo...

-

Hot sale Factory Nylon Tapes Wrapping Machine -...

-

China Cheap price Automatic Rotary Screen Print...

-

factory low price Tie Down Straps Dyeing Machin...

-

Factory For Used Automatic Soft Cards Screen Pr...