High Quality Roll To Roll Lanyard Screen Printing Machine - Seatbelts Continuous Dyeing and Finishing Machine with Ce Certificate – Kin Wah Detail:

Basic Info

Product Description

Item No: KW-800-AQS200

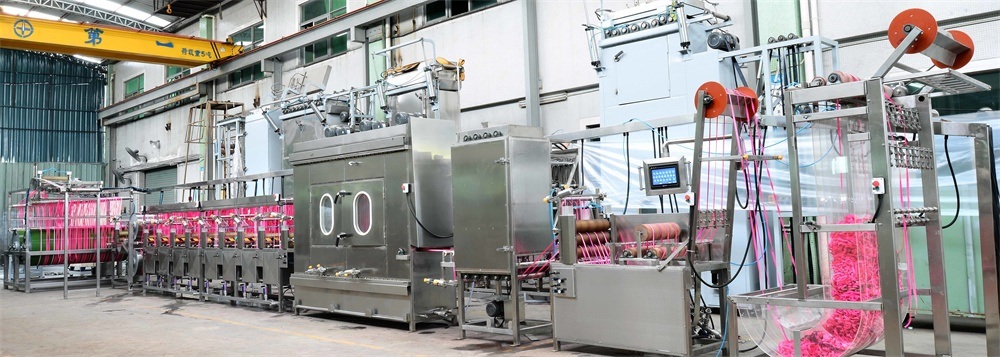

Size: 15000*1000*1800mm

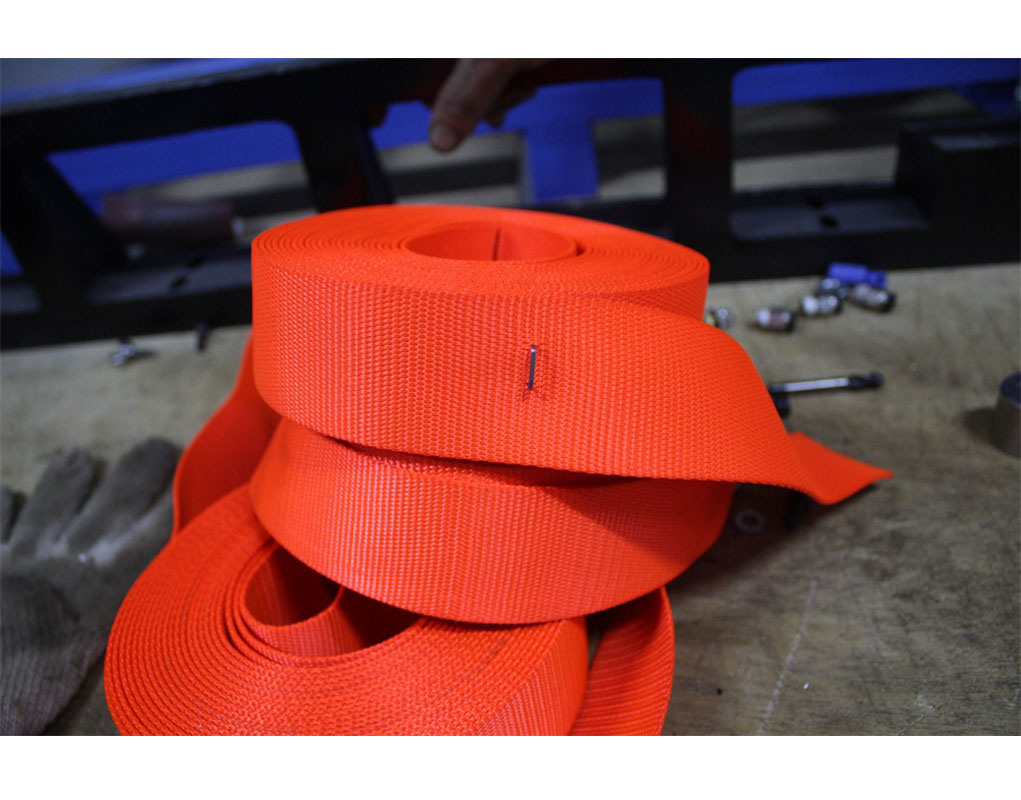

This is high speed luggage&Suitcase belts/webbing continuous dyeing machines for nylon webbings,and polyester webbings,safty webbings,lanyard ribbons,harness webbings and heavy duty webbings etc.

Features:

1) High efficiency

2) Power Energy Saving

3) Our patents.

4)Application: The dyeing machine is especially used for

luggage&Suitcase belts/webbing continuous dyeing machines

for nylon webbings,and polyester webbings,safty webbings,lanyard ribbons,harness webbings and heavy duty webbings with thickness below 1.5mm.

5)Product capacity: 1-12 Pcs/time, 0-35meter/min/Pcs.

Heat System electrical/LPG or natural gas/steam

Working Width(mm) 200/400/600

Thermofixation Chamber Tape Content(m) 45/60/60/80

Maximun Speed(m) 15/30/40

Maximun Number(m) 6/10/20

Control system Manual/Computer control(PLC&Touch screen)

Processes: Feed in-dyeing groove-Infrared pre drying-thermofixation chambers-chemical groove-steam chamber-washing tanks-chemical groove-hot air chamber drying&finishing unit-cooling system-take off

Customers: SATIN RIBBONS, ELASTIC TAPES continuous dyieng and finishing machines: MONTRIMS,ITL,GLOBAL LABEL, KINGS, LEADER,XINLIN,SANDING GROUP, BRAITEX, TELALA, WARRANTY, APEX, N R GROUP, SHORE TO SHORE, KNITTING CONCERN, STRETCHLINE, DUGOTEX SO ON.

KIN WAH Mechanical Industrial Co., Ltd. established in the year of 2005, has been dedicated in researching and developing KIN WAH dyeing and finishing equipment series for narrow fabric for more than twenty years. KIN WAH dyeing and finishing equipment series include High temperature Continuous Dyeing & finishing Machines, Normal temperature Continuous Dyeing &finishing Machines, High & Normal Temperature Continuous Dyeing & finishing Machines (same machine), Finishing & Starching Machine, Calender Machine for labels, packaging machines, rolling machines and relative narrow fabric Complete Plant programming. They are widely used for all kinds of narrow fabric made from polyester, nylon and cotton material, such as automobile seat belts (one end & two-ends), heavy duty tapes, textile lift slings, safety belts, luggage & bag belts, satin ribbons, ornament ribbons, labels, elastic tapes, organza tapes, curtain tapes, and cotton tapes.

Package:Covered by plastic membrane within full container or less container (woodencase)

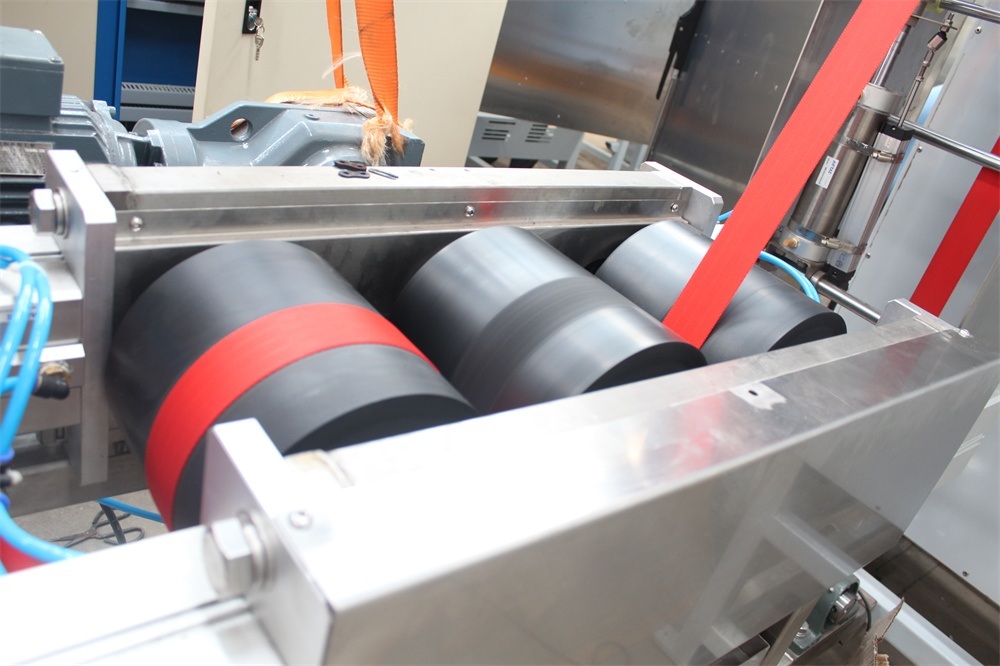

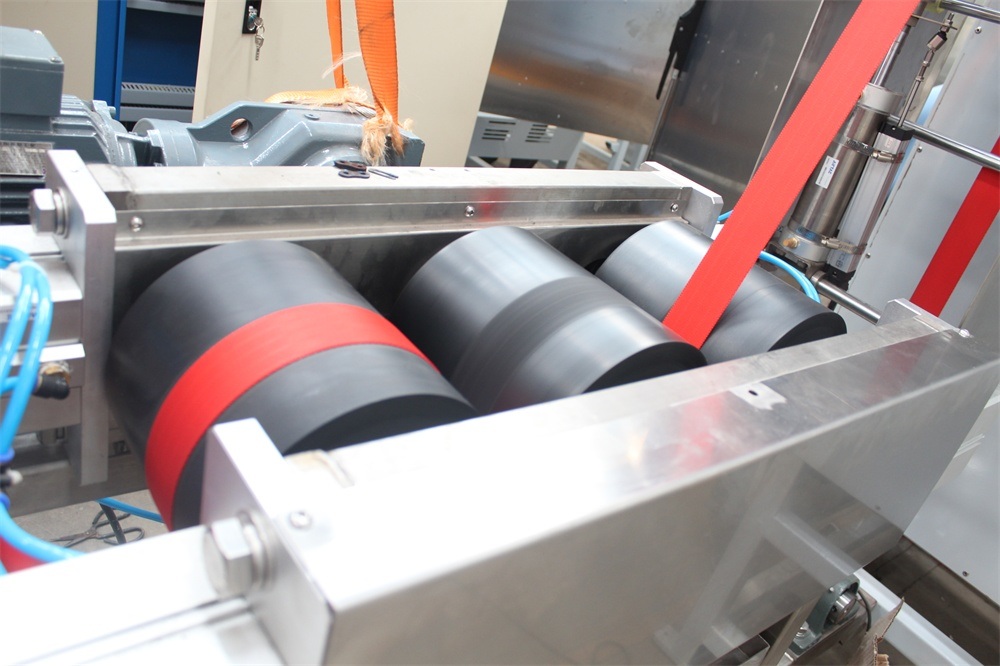

Product detail pictures:

Related Product Guide:

Siegwerk presents latest ink developments | 8 Heads Labels Winding Machine

How to Select a Commercial Screen Printer

Adhering into the principle of "quality, provider, performance and growth", we now have gained trusts and praises from domestic and intercontinental consumer for High Quality Roll To Roll Lanyard Screen Printing Machine - Seatbelts Continuous Dyeing and Finishing Machine with Ce Certificate – Kin Wah, The product will supply to all over the world, such as: Serbia , Jakarta , Greek , When you are keen on any of our goods following you view our product list, be sure to feel free to make contact with us for inquiries. You'll be able to send us emails and get in touch with us for consultation and we shall respond to you as soon as we're able to. If it's convenient, you could find out our address in our web site and come to our enterprise. or additional information of our products by yourself. We're generally ready to build lengthy and steady co-operation relations with any possible shoppers within the associated fields.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.

-

Massive Selection for Lashing Webbings Automati...

-

Factory best selling Lashing Belts Cutting Mach...

-

Popular Design for Id Card Printing Machine Pri...

-

100% Original Single Color Apparel Ribbons Scre...

-

China OEM Slitter Machine - Multitapes Dyeing ...

-

Super Lowest Price Lashing Straps Dyeing And Fi...