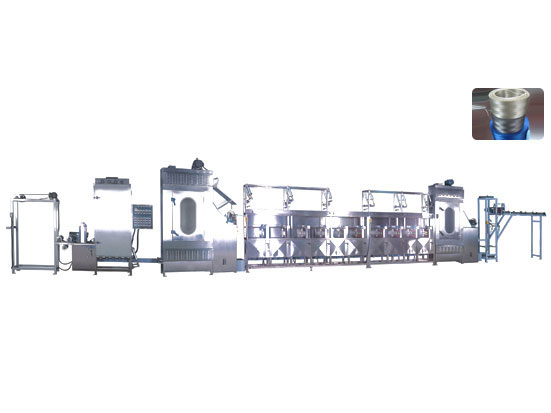

Hot sale Factory Webbings Automatic Screen Printing Machine - Best polyester luggage belt continuous dyeing and finishing machine – Kin Wah Detail:

Item No. KW-800-XB400

it’s a kind of KW-800-XB400 safety webbings, harness webbings continuous dyeing machine, it also can dye luggage and suitcase belt,safety webbings,lanyard ribbons and so on! our patent.

Application: The dyeing machine is widely used for dyeing harness webbings, safety webbings(belt) automobile webbings, lanyard ribbons, satin ribbons and so on with thickness of below 1.5mm

high efficiency

energy saving

our patent

2)Production capacity:1-12pcs/time,0-35meter/min/pcs.

| Heat System | electrical |LPG or natural gas |steam | ||

| Working Width(mm) | 200|400 | 600 | |

| Thermofixation Chamber Tape Content(m) | 45|60 | 60|80 | |

| Maximun Speed(m) | 15|30 | 40 | |

| Maximun Number(m) | 6|10 | 20 | |

| Control System | Manual | computer control( PLC & Touch screen) | ||

2)Processes: Feed in →dyeing padder→infrared predrying → thermofixation chambers → chemical padder→steam chamber →washing tanks → chemical padder→ drying and finishing cylinders →cool system→take off

Product detail pictures:

Related Product Guide:

Returned goods are a problem for retailers, resellers are cashing in | Polyester Satin Ribbons Small Continuous Dyeing Machine

Fallout 76 Main Quests Walkthrough Guide | Luggage Belt Continuous Dyeing And Finishing Machine

Every member from our high efficiency sales team values customers' needs and business communication for Hot sale Factory Webbings Automatic Screen Printing Machine - Best polyester luggage belt continuous dyeing and finishing machine – Kin Wah, The product will supply to all over the world, such as: Paraguay , Somalia , Romania , Our technical expertise, customer-friendly service, and specialized products make us/company name the first choice of customers and vendors. We are looking for your inquiry. Let's set up the cooperation right now!

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.

-

Cheapest Price Screen Printing Machine With Mic...

-

Chinese Professional Garment Labels Screen Prin...

-

factory Outlets for Ribbons Dyeing And Finishin...

-

Competitive Price for Rfid Card With Magnetic S...

-

Factory Cheap Business Card Printer - 3 Colors...

-

Factory Supply Shoulder Tapes Festooning Machin...