OEM Customized Film Slitting Machine - European Standrd seatbelt webbings continuous dyeing and finishing machine Factory – Kin Wah Detail:

MODEL NO.:KW-800-AQS200

This is a kind of High Speed European Standard Single End Automobile Seatbelt/safety webbings continuous dyeing and finishing machine.

Single End

High speed

With Elongation

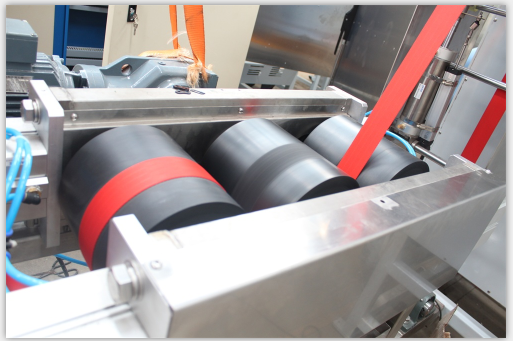

with Calender function

With Computer

Our Patent.

High efficinecy

1)Application: The dyeing machine(with PLC) is especially used for dyeing single-end type Automobile Seatbelt/Safety webbing with European standard requirement.with elongation and relative calender function.

2)Processes: Feed in →J-BOX →Accumulator →dyeing padder→Hot Air Chamber→Hold mangle→Thermosal Chamber→Heavy duty Calender→Pull Mangle→Chemical padder→Hot Steam Chamber→Washing tank→Hot Air Chamber→Cool System→Chemical padder→Infrared Predrying→Hold mangle→Final hot air chamber→Heavy duty Calender→Pull Mangle→Cool System→Take off

3)Production capacity:1 pcs/time,0-70meter/min/pcs. or 2PCS/time, 0-30meter/ min/pcs.

4)thermofixiation chamber webbing content:240meters/70meter.

2)Production capacity:1-12pcs/time,0-35meter/min/pcs.

| Heat System | electrical |LPG or natural gas |steam | ||

| Working Width(mm) | 200 | ||

| Thermofixation Chamber Tape Content(m) | 240 | ||

| Maximun Speed(m) | 70 | ||

| Maximun Number(m) | 1 | ||

| Control System | Computer control( PLC & Touch screen) | ||

| Elongation Rate | 5% Minimum, 19% Maximum | ||

Product detail pictures:

Related Product Guide:

Poland: “We don’t have the manpower to pick all these apples” | Polyester Satin Ribbons Small Continuous Dyeing Machine

Label Solutions installs Taiyo flexo press | 8 Heads Labels Winding Machine

We insist over the principle of enhancement of 'High high quality, Efficiency, Sincerity and Down-to-earth working approach' to offer you with superb assistance of processing for OEM Customized Film Slitting Machine - European Standrd seatbelt webbings continuous dyeing and finishing machine Factory – Kin Wah, The product will supply to all over the world, such as: Hanover , Honduras , Paris , We have gained a lot of recognition among customers spread all across the world. They trust us and always give repetitive orders. Furthermore, mentioned below are some of the major factors that have played significant role in our tremendous growth in this domain.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!

-

High Performance Label Ribbons Sample Continuou...

-

Bottom price Sling Webbings Screen Printing Mac...

-

China Supplier Lash Webbings Cutting And Windin...

-

Cheapest Price Polyester Rope Making Machine - ...

-

Factory selling High End Automatic Screen Print...

-

Factory directly High Quality Screen Printing M...