OEM/ODM Factory Digital Fabric Printing Machine - Cargo Webbings Automatic Screen Printing Machine Ce Approved – Kin Wah Detail:

Basic Info

Product Description

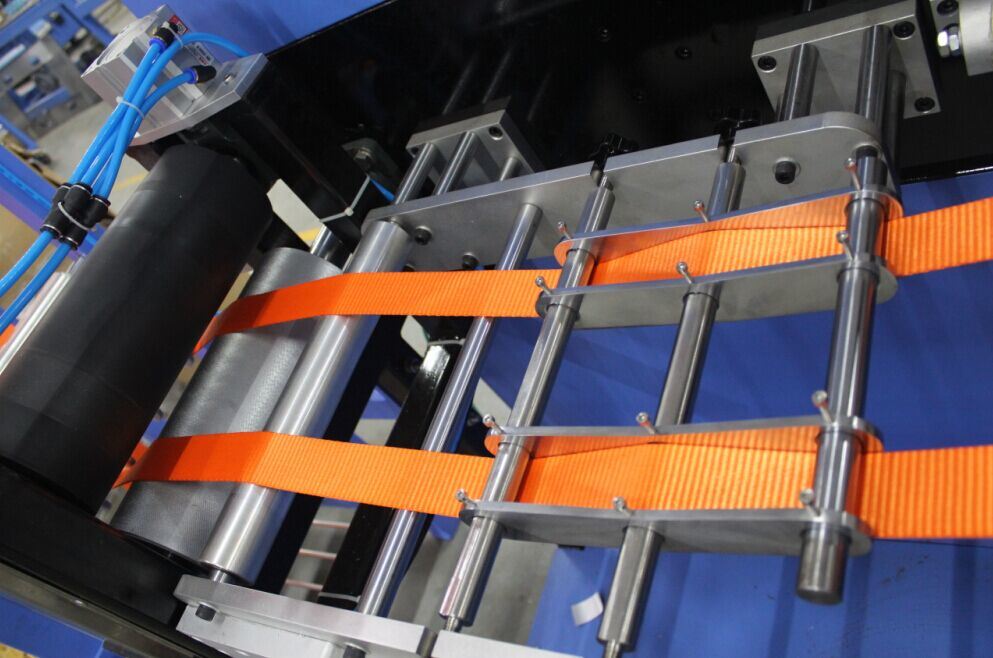

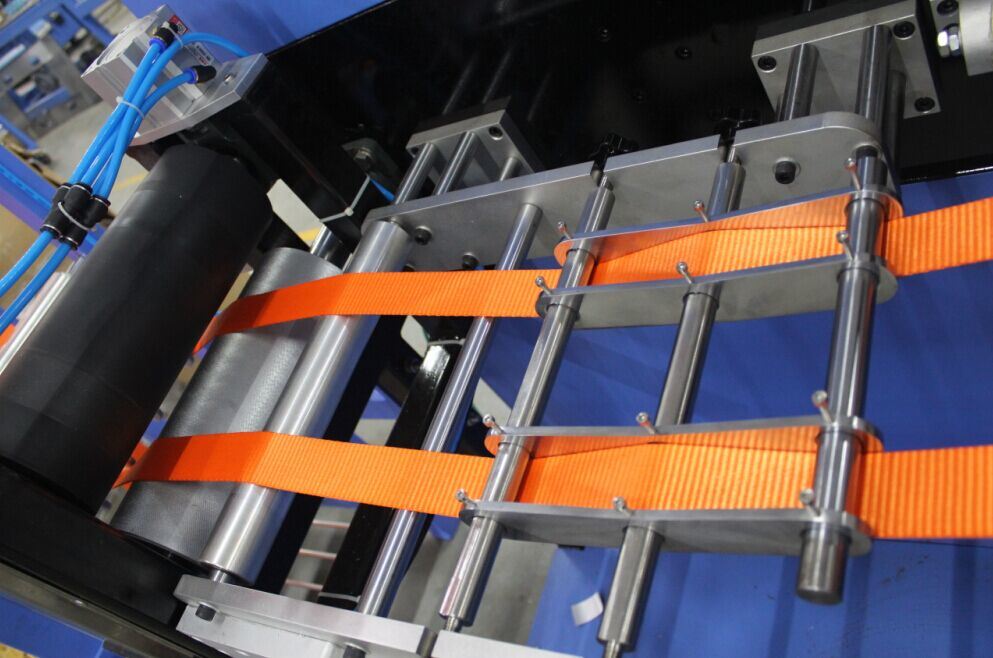

This is a kind of automatic textile lift slings webbings printing machine in screen printing type, with PLC and touch screen

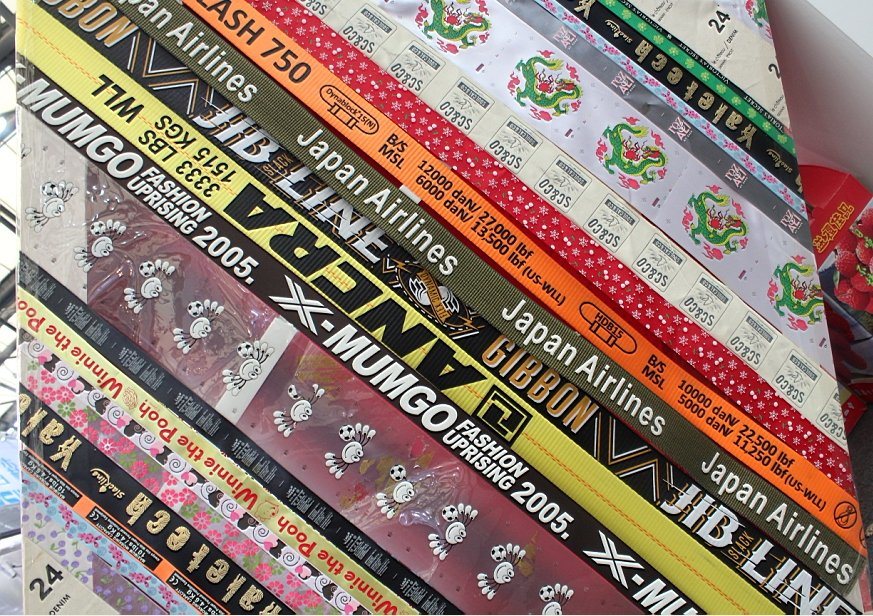

1)Application material: print any kinds of roll to roll webbings, such as seatbelt webbings, tie down straps, luggage and suitacase webbings and so on.

2)Precisely Print any roll to roll material with width<30CM.

3)convey: powered by full auto servo Motor .Not by air pressure.

4)One operator need only

5)Anti-wind device make the ribbon pulled into dryer after printing.

6)free set up the printing times and the carry times on electronic Dryer lift while stop

7)Most parts are made in Europe,Japan

8)controlled by both computer and manual.

D,machine configuration:

1) Feed in :1set frame

2) webbings rollers guiding device:1set with frame.

3) printer:1set

4)Dryer system: 1set

1)with tape content of 20meters tape content

2)heated with electrical

3)with temperature control, temperature is adjustable

4)Laid out air blower for heating webbings .

5) take off device:1set 3group of take off wheels for 6 webbings take off purpose

E. Technical specification:

1)Colore:1C

2)Max. Printing Area:30CM*130CM

3)Printing linest: 1-6LINES/ TIME

4)MAX. Speed /H.:10M/Line/Minute

5)Max. Power:20KW/380V/3P/50 Hz

Remark:1) Inverter:MISTUSBISH

2)PLC: MISTUSBISH or AB(America)

It’s widely usded by the world famous printing manufacturers,such as JULI Group, Murtra, Protekt, Astro, Hedef Halat, Ekas, Tsiros and Ferreterro, Dahua, Lijia, LiQiang

DOPSING Machinery Technology Co.,Ltd is dedicated in producing narrow fabric screen printing machine,The tech team have more than 12 years design and management experience.The New type screen printing machine has gained over 10 patents.We supply Auto Roll to Roll screen ribbon&label printing machine and mini High-Temperature Ribbon Screen Printer,label slitting machine,all are for fabric label and satin ribbon,lanyard,cotton tape etc.As the leader of the narrow fabric screen printing equipments,We have many oversea partners develop market together. Such as STRETCHLINE/PAXAR/AVERY-DENISSION/SML/ESQUEL/SHORE TO SHORE/ITL/FINOTEX/MAHEEN LABEL/DEKKO/LONGRIVER etc.

2011,DOPSING joined into the professional narrow fabric continuous dyeing and finishing machine manufacturer Dongguan City Kin Wah Machinery Co.,Ltd.And moved into KINWAH Industrial park,covering an area of more than 2000 square meters for the automatic screen printer manufacturing,researching developing together with marketing.

Product detail pictures:

Related Product Guide:

Mark Andy records successful Labelexpo Americas 2018 with 20+ digital and flexo sales | Labels Screen Printer

Death Cab For Cutie’s ‘Something About Airplanes’ Turns 20: Look Back On Their Debut | Labels Screen Printer

We've one of the most advanced generation tools, experienced and qualified engineers and workers, recognized good quality manage systems and a friendly skilled product sales workforce pre/after-sales support for OEM/ODM Factory Digital Fabric Printing Machine - Cargo Webbings Automatic Screen Printing Machine Ce Approved – Kin Wah, The product will supply to all over the world, such as: Greece , Macedonia , Iraq , Now, with the development of internet, and the trend of internationalization, we have decided to extend business to overseas market. With the propose of bringing more profits to oversea customers by providing directly abroad. So we have changed our mind, from home to abroad, hope to give our customers more profit, and looking forward to more chance to make business.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.

-

Top Suppliers Screen Stretching Machine - Chin...

-

Factory source Precision Silk Screen Printing M...

-

Discountable price Fingerprint Employee Attenda...

-

2017 New Style Single Tape Sample Dyeing Machin...

-

Cheapest Price Silk Screen Printing Machine For...

-

Cheap price Safety Belts Continuous Dyeing And ...