Short Lead Time for Nylon Bag Belts Dyeing Machine - Roll to Roll Materials Automatic Screen Printing Machine (SPE-3000S-3C) – Kin Wah Detail:

Basic Info

Product Description

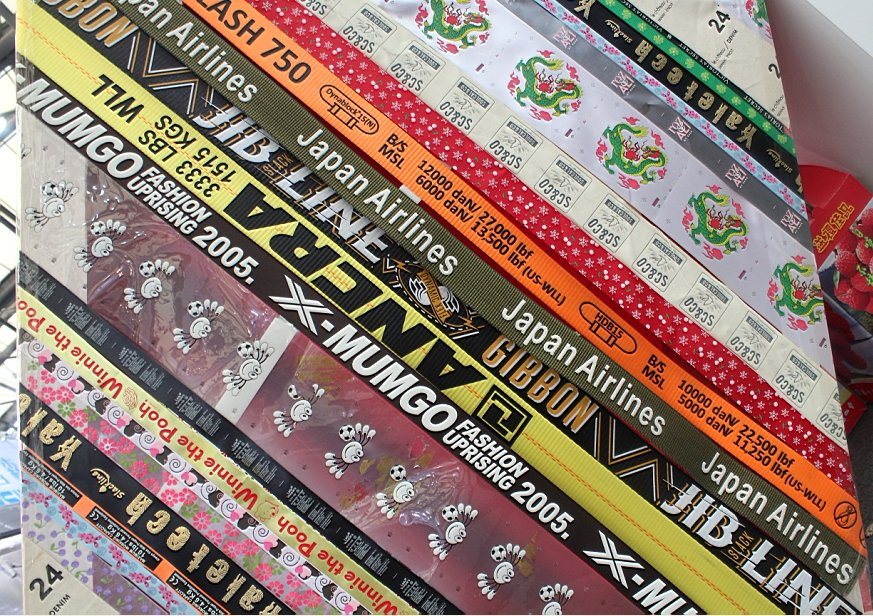

It can print any kind of roll to roll material, such as label ribbons,satin ribbons,lanyard ribbons,elastic tapes, heat transfer film,shoes laces, heavy duty webbings and so on.

Model: SPE-3000S-3C

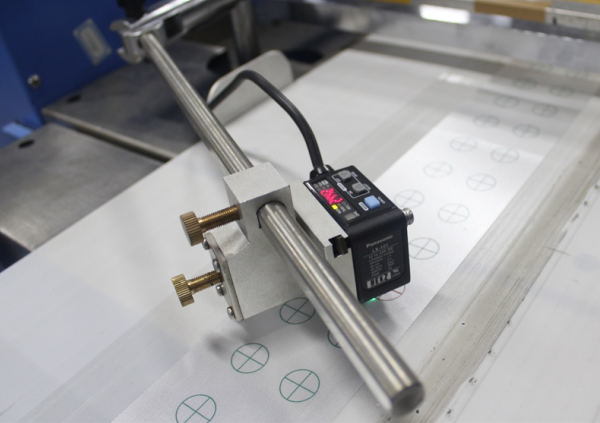

Precise printing

1)powered by full automatic Servo Moto with a Ball-Screw-Assemblies instead of air pressure.

2)Adjusting printing position by Auto Sensors system instead of handcraft.

3)Tension controller and the brake make the conveying exactly

Functions:

1)Muti-color printing, colours: This model has 1c, 2c, 3c

2)Over printing for more colors, it can print 4C~8C too

3)Both sides printing several trips at one time

4)slice printing

5)Micro adjusting meter for frame adjusting automatically.

6)Anti-wind device makes the ribbon pulled into dryer after printing.

7)Infrared dryer and heater make the any kinds ink dry enough.

8)Free set up the printing times and the carry times on electronic touch screen.

9)Several sensors tracing the situation of the feeding materials.

10)Dryer lift while the machine stopping

11)Most core parts import from Europe&Japan.

Good after service, guarantee time 12 months, and we have professional engineers to install the machine for you and train your staffs until they master the machine. All of this is free.

It’s widely usded by the world biggest narrow fabric printing manufacturers,such as PAXAR/AVERY-DENISSION/SML/ESQUEL/SHORE TO SHORE/ITL/STRETCHLINE and so on.

DOPSING Machinery Technology Co.,Ltd is dedicated in producing narrow fabric screen printing machine,The tech team have more than 12 years design and management experience.The New type screen printing machine has gained over 10 patents.We supply Auto Roll to Roll screen ribbon&label printing machine and mini High-Temperature Ribbon Screen Printer,label slitting machine,all are for fabric label and satin ribbon,lanyard,cotton tape etc.As the leader of the narrow fabric screen printing equipments,We have many oversea partners develop market together. Such as STRETCHLINE/PAXAR/AVERY-DENISSION/SML/ESQUEL/SHORE TO SHORE/ITL/FINOTEX/MAHEEN LABEL/DEKKO/LONGRIVER etc.

2011,DOPSING joined into the professional narrow fabric continuous dyeing and finishing machine manufacturer Dongguan City Kin Wah Machinery Co.,Ltd.And moved into KINWAH Industrial park,covering an area of more than 2000 square meters for the automatic screen printer manufacturing,researching developing together with marketing. it has gained over than 10 patents from generation 1 to generation 3 of computerized screen printing machine.

Product detail pictures:

Related Product Guide:

First Impression Labels invests in digital production with Screen and Rotocon equipment | 8 Heads Labels Winding Machine

How to Know if You Should Spend Forever Together | 8 Heads Labels Winding Machine

All we do is always involved with our tenet " Consumer initial, Trust first, devoting within the food stuff packaging and environmental defense for Short Lead Time for Nylon Bag Belts Dyeing Machine - Roll to Roll Materials Automatic Screen Printing Machine (SPE-3000S-3C) – Kin Wah, The product will supply to all over the world, such as: Rotterdam , Angola , Ethiopia , Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!

-

Best Price for High Temp Ink Labels Automatic S...

-

Good Wholesale Vendors Automobile Safety Belts ...

-

Factory wholesale Automatic Label Silkscreen Pr...

-

professional factory for Four Color Printing Ma...

-

Best quality Polyester Elastic Tapes Pre-Shrink...

-

Ordinary Discount Heavy Webbings Cutting And Ro...