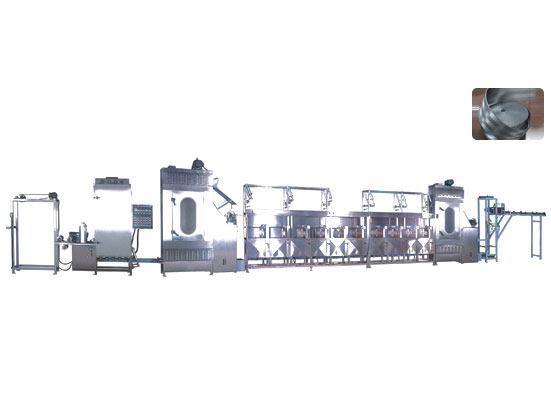

Item No. KW-800-XB400

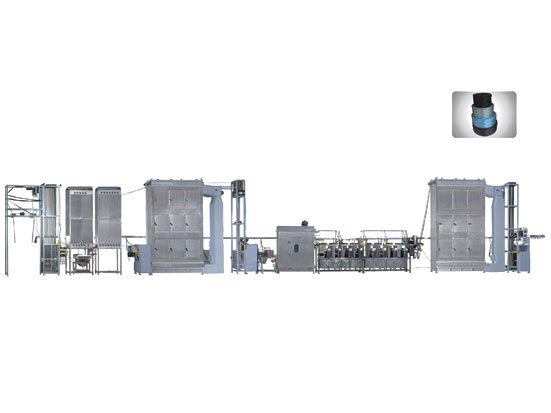

it’s a kind of automobile seatbelt webbings continuous dyeing machine. it also can safety webbings, harness webbings, luggage & suitcase webbings, lanyard ribbons and relative heavy webbings. our patent, high speed.

Application: The dyeing machine is widely used for dyeing automobile seatbelt webbings, safety webbings, harness webbings, luggage & suitcase belts/webbing, lanyard ribbons, satin ribbons and so on with thickness of below 1.5mm

high efficiency

energy saving

our patent

2)Production capacity:1-12pcs/time,0-35meter/min/pcs.

| Heat System | electrical |LPG or natural gas |steam | ||

| Working Width(mm) | 200|400 | 600 | |

| Thermofixation Chamber Tape Content(m) | 45|60 | 60|80 | |

| Maximun Speed(m) | 15|30 | 40 | |

| Maximun Number(m) | 6|10 | 20 | |

| Control System | Manual | computer control( PLC & Touch screen) | ||

2)Processes: Feed in →dyeing padder→infrared predrying → thermofixation chambers → chemical padder→steam chamber →washing tanks → chemical padder→ drying and finishing cylinders →cool system→take off