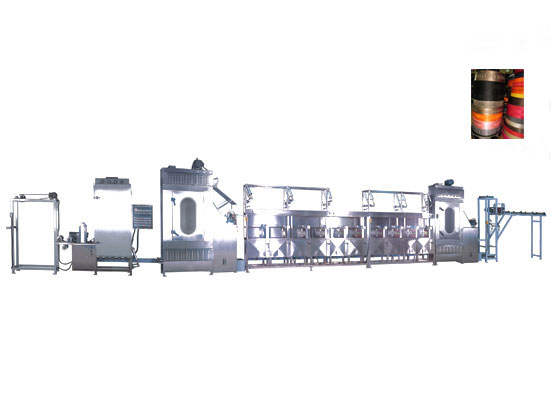

Item No. KW-800-XB400

it’s a kind of luggage & suitcase belts/webbing continuous dyeing machine for nylon webbings, and polyestr webbings,safety webbings, lanyard ribbons,harness webbings and heavy duty webbings and so on!it’s our patent.

Application: The dyeing machine is widely used for dyeing luggage & suitcase belts/webbing,harness webbings, and also can be used for safety webbings(belt) automobile webbings, lanyard ribbons, satin ribbons and so on with thickness of below 1.5mm

high efficiency

energy saving

our patent

2)Production capacity:1-12pcs/time,0-35meter/min/pcs.

| Heat System | electrical |LPG or natural gas |steam | ||

| Working Width(mm) | 200|400 | 600 | |

| Thermofixation Chamber Tape Content(m) | 45|60 | 60|80 | |

| Maximun Speed(m) | 15|30 | 40 | |

| Maximun Number(m) | 6|10 | 20 | |

| Control System | Manual | computer control( PLC & Touch screen) | ||

2)Processes: Feed in →dyeing padder→infrared predrying → thermofixation chambers → chemical padder→steam chamber →washing tanks → chemical padder→ drying and finishing cylinders →cool system→take off