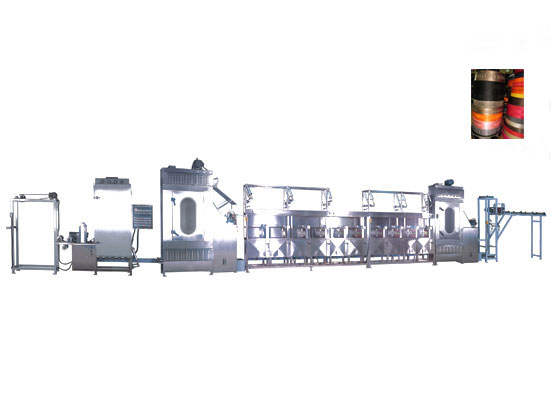

KW-800-XB400-L Luggage&Suitcase belts continuous dyeing and finishing machine

Item No: KW-800-XB400-L

Size: 25500*1300*2400mm

This is high speed luggage&Suitcase belts/webbing continuous dyeing machines for luggage&Suitcase belts/webbings,and polyester webbings,safty webbings,lanyard ribbons,harness webbings and heavy duty webbings etc.

Features:

1) High efficiency

2) Power Energy Saving

3) Our patents.

4)Application: The dyeing machine is especially used for luggage&Suitcase belts/webbing

nylon webbings,and polyester webbings,safty webbings,lanyard ribbons,harness webbings

and heavy duty webbings with thickness below 1.5mm.

5)Product capacity: 1-12 Pcs/time, 0-35meter/min/Pcs.

| Heat System | electrical | LPG or natural gas | steam |

| Working Width(mm) | 200 | 400 | 600 |

| Infrared predrying(m) | / | 45 | / |

| Thermofixation

Chamber Tape Content(m) |

45 | 60 | 120 |

| Maximun Speed(m) | 15 | 30 | 40 |

| Maximun Number(m) | 6 | 10 | 20 |

| Control system | Manual/Computer control(PLC&Touch screen) |

Processes: Feed in-dyeing groove-Infrared pre drying-thermofixation chambers-chemical groove-steam chamber-washing tanks-chemical groove-hot air chamber drying&finishing unit-cooling system-take off